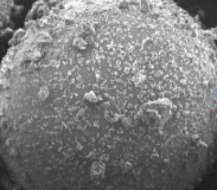

Expanded Microspheres

EXPANDED MICROSPHERES

- Expanded microspheres are used in applications where there isn’t enough heat in the process to use unexpanded products.

- We blend unexpanded microspheres with calcium carbonate and expand them using a patented process.

Important process parameters to help you choose which Dualite Microspheres

1. Determine particle size and density requirements are right for your application?

2. How aggressive is the manufacturing process (shear, heat, pressures, chemical exposure)?

3. Finished product type, application, and requirements?

| FEATURES | ||

| In Process | Reduces | Properties |

| • Sprayable | • Cost | • Non-friable |

| • Shear Stable | • VOC | • Compressible |

| • Pumpable | • Weight | • Flexible |

Product Stability: The performance of DUALITE® is dependent on the cumulative effects of temperature, pressure and chemical environment. Since Chase Corporation is not able to exhaustively test all combinations of these variables, this data is furnished as a guideline for selection of an appropriate grade of DUALITE®.

| Dualite® E Grade – Typical Properties | |||

|

Product Name |

Nominal Density (g/cc) |

Particle Size Mode (Peak) |

Shear Stability |

|

E030 |

0.030 +/- 0.005 |

125-145 μm |

30-50 μm |

|

E035-FR |

0.035 +/- .015 |

70-100 μm |

Better |

|

E035-FR |

0.035 +/- .015 |

145-165 μm |

Good |

|

E065-135D |

0.065 +/- 0.005 |

125-145 μm |

Good |

|

E065-135D |

0.130 +/- 0.015 |

45-65 μm |

Better |

|

E065-135D |

0.130 +/- 0.015 |

85-105 μm |

Best |

|

E065-135D |

0.130 +/- 0.015 |

95-115 μm |

Good |

|

E130-040D |

0.135 +/- 0.015 |

30-50 μm |

Better |