LiquiSAp™ Coatings Enable New Levels of Performance

liquid superabsorbent applied to a nonwoven substrate

ETi LiquiSAp Technology is a liquid polymer product platform engineered to impart exceptional superabsorbent functionality to both flexible and non-flexible substrates.

1. How to use it

ETi LiquiSAp can be applied via industry-standard liquid application methods such as:

- Dip coating

- Spray coating

- Inkjet printing

- Kiss roll

- Those treated substrates must then be cured with heat above 135ºC

2. Where to use it

This technology will find a quick and easy home as a drop-in replacement to many existing liquid superabsorbents currently used in the Wire & Cable industry.

Due to its unique set of features and benefits, ETi LiquiSAp is also an excellent candidate for use in the treatment of nonwoven fabrics often found in personal hygiene articles.

ETi LiquiSAp™ Technology – Photos / Performance

Uncoated (PP fiber ~10-15 µm)

LiquiSAp ~30wt% (Flexible SAP region) (PP fiber ~10-15 µm)

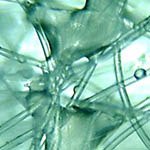

ETi LiquiSAp™ >coated nonwoven (~20 wt%) before DI water soak) (PP fiber ~10-15 µm)

Swollen nonwoven after ~5 min DI water soak; DI water absorption: ~21g/g

Applicable across a wide array of materials

- Yarns

- Fiberglass

- Aramid

- Polypropylene

- Nonwoven Fabrics

- Spunlace

- Meltblown

- Airlaid

Aqueous based chemistry

- No VOCs

Single component, ready-to-use

Low viscosity

Stable product

- Shelf life > 180 days

Formulated to provide unparalleled performance

- Fast speed of absorption, high absorption capacity, good gel strength

Customizable formulations are possible

Functional across broad operating conditions

- Oven type

- Oven temperature

- Roller speed

Soft, clear, non-flaking film finish

- Virtually undetectable on substrates

- LiquiSAp 1000 – low viscosity, broad application product

- LiquiSAp 2000 – higher viscosity for specialized application methods

- LiquiSAp HP – for applications requiring minimal coating levels where high loadings cannot be tolerated

- LiquiSAp NA – Non-Aqueous formulation that does not require curing; for specialized industrial applications

This is a Chase Corporation proprietary formulation that was designed from the ground up to specifically address all of the known issues that Wire and Cable manufacturers report experiencing with existing liquid superabsorbent products. When applied and cured correctly, LiquiSAp provides the following characteristics:

Drop-in replacement for many existing liquid superabsorbent products

Fast absorption speed

High absorption capacity

Functionality across a wide range of operating conditions and substrates

Shelf stability, 180+ days

High resistance to microbiological growth

Easy to handle, low viscosity

No VOC formulation

Soft, clear, non-flaking film finish

No, LiquiSAp comes as a ready-to-use product.

Yes

While LiquiSAp does not require any additives, we understand that some customers may want to include them. Please contact us to confirm compatibility.

- Features & Benefits

-

Applicable across a wide array of materials

- Yarns

- Fiberglass

- Aramid

- Polypropylene

- Nonwoven Fabrics

- Spunlace

- Meltblown

- Airlaid

Aqueous based chemistry

- No VOCs

Single component, ready-to-use

Low viscosity

Stable product

- Shelf life > 180 days

Formulated to provide unparalleled performance

- Fast speed of absorption, high absorption capacity, good gel strength

Customizable formulations are possible

Functional across broad operating conditions

- Oven type

- Oven temperature

- Roller speed

Soft, clear, non-flaking film finish

- Virtually undetectable on substrates

- Yarns

- Product Specifications & Sizes

-

- LiquiSAp 1000 – low viscosity, broad application product

- LiquiSAp 2000 – higher viscosity for specialized application methods

- LiquiSAp HP – for applications requiring minimal coating levels where high loadings cannot be tolerated

- LiquiSAp NA – Non-Aqueous formulation that does not require curing; for specialized industrial applications

- Frequently Asked Questions

-

How is this product different than other liquid superabsorbent products on the market?

This is a Chase Corporation proprietary formulation that was designed from the ground up to specifically address all of the known issues that Wire and Cable manufacturers report experiencing with existing liquid superabsorbent products. When applied and cured correctly, LiquiSAp provides the following characteristics:

Drop-in replacement for many existing liquid superabsorbent products

Fast absorption speed

High absorption capacity

Functionality across a wide range of operating conditions and substrates

Shelf stability, 180+ days

High resistance to microbiological growth

Easy to handle, low viscosity

No VOC formulation

Soft, clear, non-flaking film finish

Does this product require any additives?No, LiquiSAp comes as a ready-to-use product.

Is this product compatible with any additives?Yes

Is EcoFlow compostable?While LiquiSAp does not require any additives, we understand that some customers may want to include them. Please contact us to confirm compatibility.

Need More Information?

Useful links

- Chase Corp/ETI Proprietary Formulation

- Manufactured in the USA