Microspheres

Expanded Microspheres

Density and size of microsphere modified to reduce weight, lower cost and enhance physical properties.

Unexpanded Microspheres

Polymeric microspheres utilizing in-situ heat to expand for optimum functionality.

Master Batch

Unexpanded microspheres compounded with a resin carrier resulting in a closed cell system which improves dispersion.

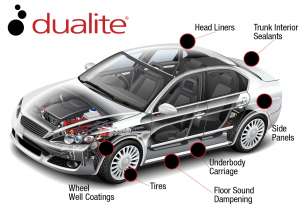

Dualite Microspheres Applications

Dualite microspheres are created through a patented process that controls expansion and coating applications. Learn where microspheres can be used.

Chase Corporation is an industry leader in Expanded Polymer Microspheres and its Dualite® products offer unique solutions to meet the needs of the numerous industries and a broad spectrum of end-use applications.

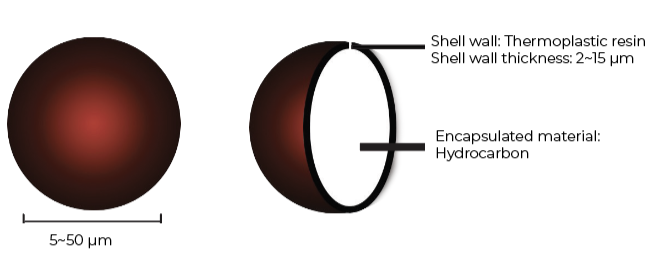

WHAT ARE MICROSPHERES

Dualite® Microspheres are microscopic ultra-lightweight fillers made from a flexible polymer shell. The microspheres come in 2 forms: Unexpanded microspheres that can expand in process as an alternative to blowing agents, and Pre-expanded microspheres.

Dualite® can be added to plastics, resins, adhesives, and composites. Their inclusion produces a number of benefits depending on the application, including lower density, reduced cost, improved insulation, VOC reduction and improved machining.

MICROSPHERE FEATURES & BENEFITS

|

|

|

|

| Density | Price Reduction | Lightweight | Sound Dampening |

Chase’s Microspheres: A Lightweight Filler Breakthrough

Products are created through a patented process that controls expansion and coating application, resulting in lightweight filler with a range of particle sizes, densities, and materials. Dualite Polymer Microsphere products offer unique solutions to meet the needs of numerous industries and a broad spectrum of end-use applications.

MICROSPHERE ENVIRONMENTAL BENEFITS

- REDUCE WEIGHT -Use less raw materials (adding 1-3% by weight of Dualite can reduce weight by15-20%) LOWERING SHIPPING COSTS.

- VOC’S – Impedes solvent migration during mixing/manufacturing process.

- R VALUE – Increased when using Dualite

- ENERGY – Water based system can dry faster since Dualite takes up more space in mix

- BLOWING AGENTS – You can replace chemical blowing agents with unexpanded microspheres giving your a safer workplace

- IMPROVED FUEL EFFICIENCY – Dualite products make sealants and coatings lighter improving the fuel efficiency of the vehicles that they are used in

- SOUND DAMPENING – Helps reduce vibration and sound emissions mean quieter spaces inside vehicles and less noise pollution

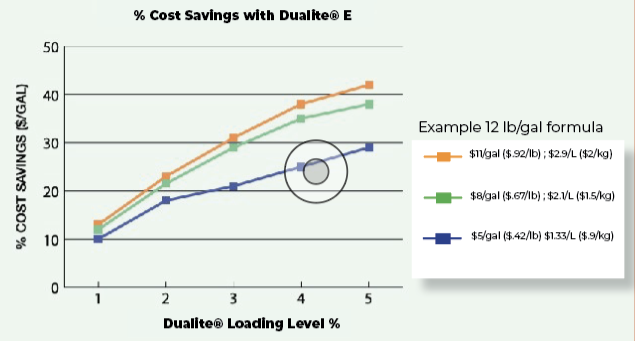

MICROSPHERE COST SAVINGS

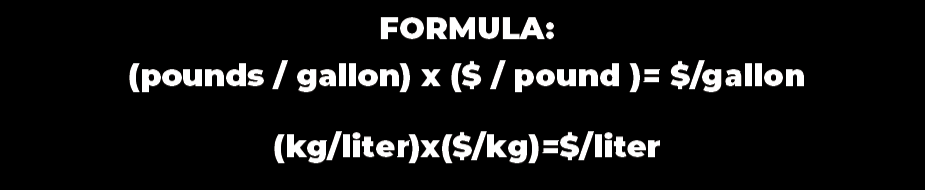

Using Dualite® E & Dualite® U can result in significant cost savings for your formula. Because of its extremely low density, Dualite® E volumetrically replaces other more expensive raw materials. The volume replacement ability of Dualite® E means that you must understand the volume costs of your current product.

To calculate the volume cost of your formula, simply multiply the weight per gallon (WPG) by the dollars per pound of the formula.

Example: A formula at 12 pounds/gallon (7 kg/liter) with a cost of $0.92/pound ($2 kg) would have a volume cost of $11/gallon ($2.9/liter).

To calculate your own formula savings, Chase can supply a spreadsheet math model that allows you to enter your own formula, raw material cost, and specific gravities.

Dualite® provides cost savings by replacing expensive raw materials, but it can also help reduce shipping expenses and energy consumption.

Download our Cost Savings Calculator Tool

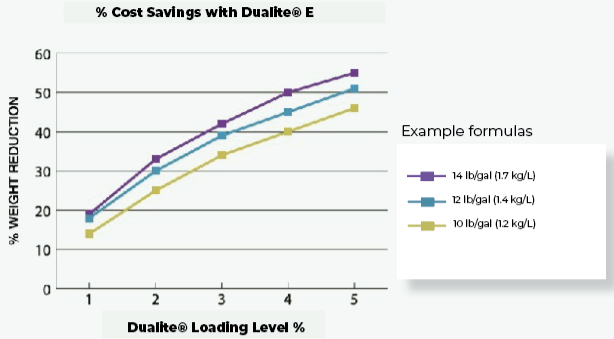

MICROSPHERE WEIGHT REDUCTION

Using Dualite® E & Dualite® U can result in a considerable weight reduction of your product. Because of its extremely low density, Dualite® volumetrically replaces other more dense raw materials.

The reduction of weight of your product achieved when using Dualite® can lead to easier handling, both internally and by your customers. This weight reduction can also have other benefits, such as freight savings.

To better understand the potential weight reduction achievable when using Dualite®, you must know the specific gravity of your current product.

To calculate your own weight reduction, Chase can supply a spreadsheet math model that allows you to enter your own formula, raw material cost, and specific gravities.

The chart demonstrates the percent weight reduction for formulas with initial specific gravities of 10, 12, and 14 pounds/gallon (1.2, 1.4, and 1.7 kg/liter) at different loading levels of Dualite® E065-135D.

Need More Information About Microspheres?

Useful links

Learn More with our Microspheres Blog Articles:

Microspheres Aren’t Rocket Science, But They Are Used In It

Improving Silicone Formulations with Polymeric Microspheres

8 Ways Polymeric Microspheres Reduce Material Costs

Improving Material Properties of Sealants with Polymeric Microspheres

Solving Weight and Buoyancy Challenges with Polymeric Microspheres

Concentration Guidelines of Using Polymeric Microspheres

When to Use Expanded Microspheres versus Unexpanded Microspheres

Advantages of Using Polymeric Microspheres in Fiber Reinforced Plastic Applications