Expansion Joints

Expansion Joints

CEVA® Joint Systems are used as expansion joints in bridge construction and in architectural applications. They offer design flexibility and cost savings as compared to other types of expansion joints. CEVA Joint Systems utilize closed-cell foam materials. Significant advantages include excellent resistance to chemicals and hydrostatic pressure as well as UV protection and noise suppression. CEVA® Joint Systems’ unique closed cell foam designs are combined with epoxy bonders and elastomeric concrete to offer superior strength and flexibility.

No, we can manufacture the size, depth, width, and length to the details of the project.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

The expansion joints can function between 60% compression and 30% tension as well as handling up to 50% horizontal or vertical shear movement.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

Bonder #1 will adhere to damp surfaces.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

38 degrees Fahrenheit is the minimum temperature requirement for installation.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

Chase can fabricate the required angles in our fabrication shop.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

| CEVA Expansion Joints Systems | Competition |

| UV Protection Package Silicone Topping is not Required | UV Stability |

| Closed-Cell Structure provides long-term durability and moisture impermeability | UV Resistant Silicone Topping Required |

| Excellent Resistance to Chemicals and Hydrostatic Pressure | Variable Resistance to Chemicals and Hydrostatic Pressure |

| Dynamic Range of Movement up to 50% | Varying Range Movement |

| Fabricated to a wide variety of sizes and widths |

Architectural expansion joint applications

Roadway/bridge expansion joint applications

- Frequently Asked Question

-

Do you have standard sizes?

No, we can manufacture the size, depth, width, and length to the details of the project.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

Is a silicone topping required?No, Ceva Expansion Joint systems do not require a silicone topping.What is the movement capabilities?The expansion joints can function between 60% compression and 30% tension as well as handling up to 50% horizontal or vertical shear movement.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

Can The Installation Occur In Wet Conditions?Bonder #1 will adhere to damp surfaces.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

Is There A Minimum Temperature Requirement?38 degrees Fahrenheit is the minimum temperature requirement for installation.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

How Are Expansion Joint Corners Produced?Chase can fabricate the required angles in our fabrication shop.

Need more info? Contact us

Need a sample? Request it here

Need Data Sheets? Access to Library

- Expansion Joints Comparison

-

CEVA Expansion Joints Systems Competition UV Protection Package Silicone Topping is not Required UV Stability Closed-Cell Structure provides long-term durability and moisture impermeability UV Resistant Silicone Topping Required Excellent Resistance to Chemicals and Hydrostatic Pressure Variable Resistance to Chemicals and Hydrostatic Pressure Dynamic Range of Movement up to 50% Varying Range Movement Fabricated to a wide variety of sizes and widths - How-to Videos

-

- Installation Details

-

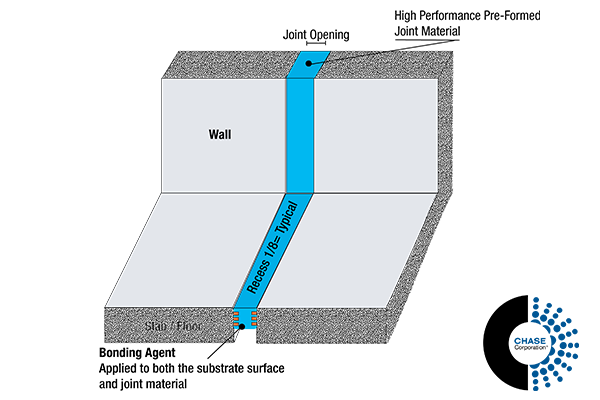

Architectural expansion joint applications

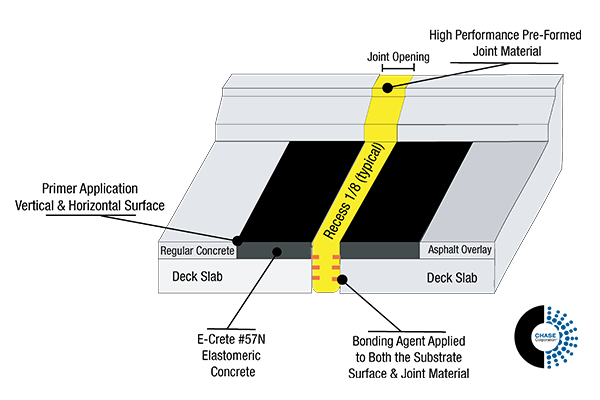

Roadway/bridge expansion joint applications

Preformed Foam Joint |

Phyzite 380™

- Cross-linked Ethyl Vinyl Acetate-Polyethylene foam joint seal

- Expands and contracts with the movement of the structure

- Provides resistance to chemicals and hydrostatic pressure

- Handles impacts without spalling or tearing

- Easy-to-install

- UV resistant closed cell foam

- Used on a variety of waterproofing applications

Preformed Foam Joint |

Metazeal

- Polyethylene foam joint seal

- For operating temperatures from -94°F to 212°F

- Expands and contracts with the movement of the structure

- Provides resistance to chemicals and hydrostatic pressure

- Handles impacts without spalling or tearing

- Easy-to-install

- Used on a variety of waterproofing applications

Preformed Foam Joint |

Metazeal AJ

- Cross-linked Ethyl Vinyl Acetate-Polyethylene foam joint seal

- For operating temperatures from -94°F to 160°F

- Provides resistance to chemicals and hydrostatic pressure

- Handles impacts without spalling or tearing

- Easy-to-install

- Minimal UV resistance – not to be used in applications exposed to UV light

- Used on a variety of waterproofing applications

General Purpose Seal Foam |

Eva-Seal/Flex-Seal

- Cross-linked EVA (Ethylene Vinyl Acetate) copolymer foam

- Expands and contracts with the movement of the structure

- Provides watertight seal

- Easy-to-install

- Typical applications include use as a concrete forming material and secondary seal.

Elastomeric Concrete |

Ecrete 57N

- 100% solids, self-leveling elastomeric concrete header material

- Ability to absorb energy from impact loads

- Reduces cracking and spalling

- Rapid return to service

- Excellent adhesion to asphalt, concrete and steel surfaces

- Three component premeasured modified urethane and aggregate system

Epoxy Bonder |

Eva-Pox Bonder #1 Beige/Grey

- Two-component 100% solids premeasured epoxy adhesive

- Bonding agent for pre-formed closed cell foam joints and ECrete 57N

- Adheres well to elastomeric concrete, cured concrete, and steel

- Offered in either beige or grey color to match the surrounding substrate.

Expansion Joints

Expansion Joints