Discover the True Power of VYBAR Candle Additive

May 17, 2023

What are Vegan-Friendly Biopolymers for Cosmetics?

October 19, 2023Expanded Polystyrene (EPS), commonly known as polystyrene foam, has a reputation for being environmentally unfriendly. It is similar to Styrofoam and often used in packaging. However, when it comes to insulation, EPS proves to be a vital player in the fight against climate change.

EPS is a lightweight, moldable insulation material derived from styrene monomer. Despite its association with single-use consumer products, EPS has several eco-friendly properties that make it an excellent choice for insulation in buildings.

How EPS Insulation Promotes a Green Future

Carbon emissions and single-use material waste are significant contributors to our global ecological crisis. EPS foam insulation addresses both issues. Energy consumption required to maintain consistent temperatures within buildings is often overlooked, yet it plays a considerable role in generating carbon emissions. There are a few ways to combat this. One method would be to look toward renewable sources of power that are carbon neutral. The other would be to cut back on the power spent maintaining habitable temperatures within buildings.

Renewable energy efforts show a lot of promise but will take time and infrastructure to fully adopt. The other solution is to cut back on the energy use for thermoregulating buildings. This can be done effectively and immediately through improving practices in securing the “building envelope”, or the systems designed to regulate temperature, air, and water exposure between the interior and exterior of a building.

This need to cut back on energy consumption is popularizing EPS foam insulation due to its low cost and high performance, outshining many other commercially available insulation materials.

Its advantages as an insulation material include:

- Lightweight, making it easy to use in construction

- Moisture-repelling, preventing mold and fungal growth

- Flame-retardant when mixed with the right additives

- Easily shapable on-site for various applications

- Long-term R-Value (“R” is the resistance to heat flow)

- Energy efficiency

- Constant thermal resistance

- Measurable energy savings

- Strength

- Sustainability

- No growth of bacteria, nor will it decay over time

- Dimensional stability

- Low cost

These properties ensure that buildings consume less energy for heating and cooling, reducing their environmental impact significantly.

Recyclable EPS Foam

EPS foam is recyclable, and Europe especially has been leading the charge in reusing and producing recycled EPS foam. EPS can be easily heated, melted, and reshaped for different applications. As such, we are seeing an upsurge in foam-protected packaging restructured for future use in both shipping and insulation.

There are two main methods of producing EPS: extruded production and suspension production. Extruded production supports breaking down existing EPS material and reforming it with fresh additive beads. Recycling EPS foam through extruded production can be as effective as creating a new product. Improving the prevalence of EPS recycling will have a tremendous impact on our landfills, and our industry knows this.

We’re witnessing a global push to establish recycled EPS foam as the norm. There is no denying that EPS foam is an incredible material for protecting packaging during transit, and now we’re approaching a future where said packaging is as recyclable as the cardboard boxes it comes in.

Both extruded and suspension manufacturing require processes of nucleating agents to ensure consistent production and desirable characteristics. These additives are essential in creating the high performance necessary for construction and packaging applications.

Nucleating Agents in EPS Foam Production

The science behind nucleating agents is complex. Nucleating agents provide the sites necessary for cell formation during the course of polymerization of polystyrene. They are dispersed in the styrene monomer prior to the initiation of the polymerization reaction. This agent modifies the chemical structure of the foam, creating large and consistent cells throughout the material. This lowers the foam density and increases its sturdiness.

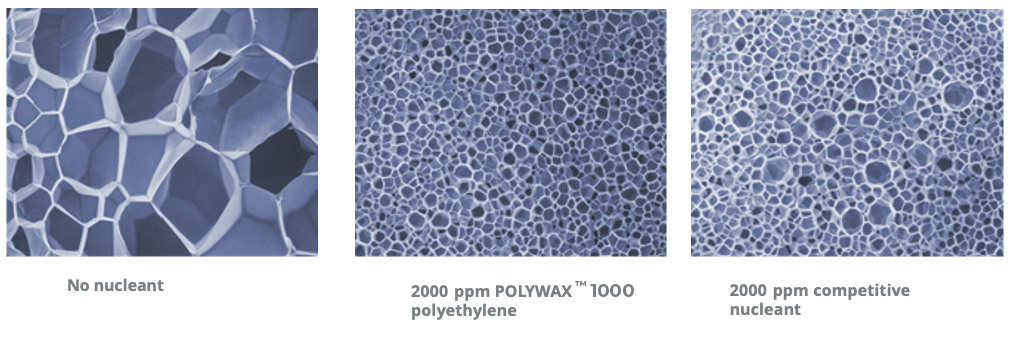

POLYWAX polyethylenes can yield a more narrow polymer bead size distribution, a smaller, more uniform cell structure, and improved density/thermal insulation properties of the finished expanded components. As a result, they have been the industry standard for EPS nucleation. They also provide potential improvement in mold cycle time, in mold fusion, surface appearance of the finished foam article and structural integrity. Many of these have been seen in actual commercial usage of the POLYWAX materials.

Effect on EPS Cell Structure

The photos below are of EPS beads, taken with a Scanning Electron Microscope (SEM), at 50X magnification. Note the development of small uniform cells when POLYWAX polyethylene is used as the nucleant.

POLYWAX™ Polyethylene

There are plenty of nucleating agents on the market, but the best nucleating agent today has remained the same for the last 25 years. When we brought nucleating agents to market two and a half decades ago, we did so with a deep understanding of the science behind expanded polystyrene. We saw the potential of the material and knew what the market needed to truly succeed. That future-sighted view maintains today as we continue to evolve our business to meet the growing need for promoting recyclable EPS.

When we say polystyrene foam is not only a green material but will also be a critical player in protecting our planet for years to come, we mean it! The advanced insulation properties of EPS foam will radically cut down our energy consumption, thus lowering carbon emissions. More so, its remarkable ability to be recycled into additional EPS foam not only cuts back overproduction of the material but can go a long way in lowering the footprint of existing landfills. Imagine the impact we’d have by creating valuable housing components from those old take-out food containers and packing peanuts! This is the future we can all work towards!

Our understanding of the chemistry is unrivaled. We have in-house experts dedicated to the study of EPS formulations. So if you’re in the business of EPS production, reach out! Our specialists are some of the best researchers out there in the space. It’s how we’ve ensured our nucleating agents promote the production of higher-quality EPS than any of our competition. Check our site for more information. Alternatively, you can contact us directly and speak with an EPS specialist.