Understanding the Real Benefits of Biopolymers in Skincare Products

March 24, 2023

EPS Insulation: An Unlikely Ally in the Fight Against Climate Change

July 10, 2023Enhancing Candle Quality with VYBAR™ Polymers Additives

Candles come in many shapes and sizes; and for as many shapes and sizes as there are, a diverse range of materials go into the candle-making process. Whether we’re discussing recreational candlemakers or industrial candle companies, the process of making candles often boils down to chemistry over craftsmanship.

This starts simply enough. The base of all candles is wax. While luxury, organic waxes exist—palm wax, soy wax and beeswax, for instance—most candles today use paraffin wax. There are a few reasons for this. First and foremost, paraffin wax is the cheapest material on the market. More importantly, the chemical properties of paraffin waxes are incredibly well-suited for candles. They boast good strength, provide consistent burn times, and boast a good compatibility with a wide range of fragrance types.

They may not burn as cleanly as other materials (you’ll notice black soot after burning), but their general characteristics have largely cemented themselves as the default for most candle makers. However, paraffin wax is just the start of this discussion.

What Are VYBAR Polymers?

VYBAR™ polymers are a tried and tested candle additive manufactured in the same location since its original inception, and currently produced by NuCera Solutions.

Paraffin wax is rarely used by itself in professional applications. Most candles mix in a VYBAR polymer candle additive: one of several types of VYBAR polymers depending on the type of candle. Generally speaking, VYBAR polymers are a type of organic polymer that builds off the good characteristics of paraffin, with a range of benefits that are nothing short of incredible.

When added to a candle, VYBAR increases:

- Opacity

- Fragrance Loads

- Consistency in batches

- Plasticity/Malleability

- Hardness

- Dye Dispersion

- Surface gloss

VYBAR improves on the material properties of candle wax across the board. Increased strength enables paraffin candles to stand tall, even while burning—making VYBAR essential for column candles. The added opacity and dye dispersion greatly improves a candle’s appearance. When this is coupled with the improved fragrance load, candles look and smell better; and this improvement isn’t subtle.

VYBAR reduces a phenomenon called mottling in the candle. Mottling refers to the splotchy patterns (the snowflakes) that appear when wax hardens.

If you’re looking for a consistent, uniform candle surface, VYBAR polymers are a necessity. In addition to reducing mottling, VYBAR also:

- Reduces cracking

- Reduces the time to cool

- Reduces raw material costs

- Eliminates oil bleed

- Eliminates surface bubbling

With all these traits in mind, VYBAR polymers are truly the secret ingredient for creating incredible, professional candles.

How to Choose the Right VYBAR Polymer

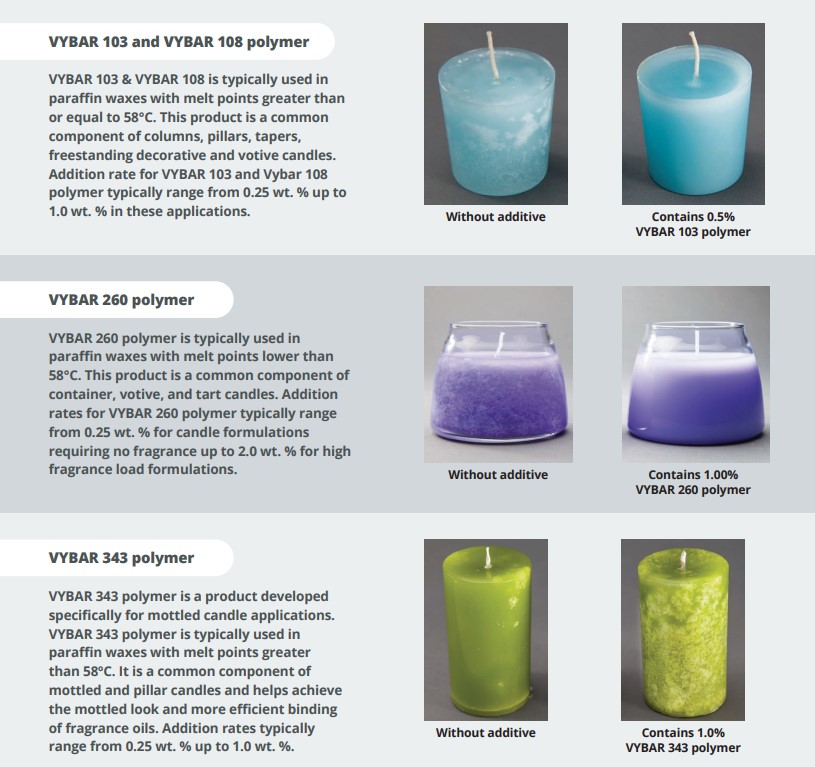

In our “benefits” list, we referenced both improved plasticity and improved hardness. How is that possible? Up to this point, we’ve been using “VYBAR” as a catch-all term. There’s more than one type of VYBAR polymer on the market. VYBAR is branded numerically. We’ve broken it down into the following table for clarity:

Innovative VYBAR™ polymers provide solutions to your paraffin candle problems, improve candle performance, and deliver value that you will recognize. VYBAR polymers are hyper-branched polyalphaolefins recognized worldwide for their ability to improve the total performance and value of candles based on paraffin waxes.

If you’re interested in learning more about VYBAR polymers for candles, reach out! Our team is more than happy to discuss the unique needs of your application. After all, when it comes to VYBAR polymers, there’s no one better to trust than the original inventors!