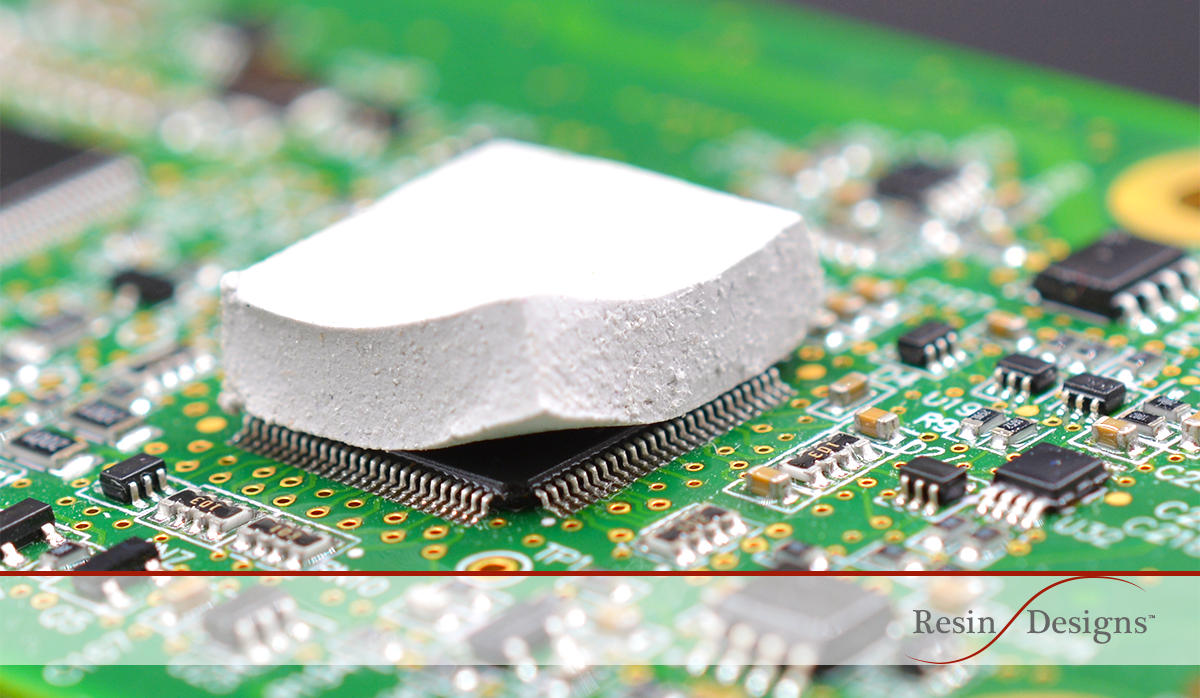

Thermal Gap Pads & Fillers

Long-term, reliable protection of sensitive circuits and components is important in today’s delicate and demanding power electronics applications. With the increase in processing power, charging wattages and the trend toward smaller, more compact electronic modules, transfer of thermal energy to heat sinks, cooled chassis and other safe locations is essential in maintaining component temperatures within operating specification limits. Resin Designs’ family of thermal interface pads provide superior performance with a variety of thermal pad constructions to achieve excellent thermal protection and economic value over a wide range of applications.

- Soft/compressible yet resilient and low compression set

- Fully cured for improved thermal cycling without pump-out concerns

- Provides low stress on the component

- Perfect for non-parallel or rough surfaces

- Consistency with manual application and minimal experience

- TIM pads are easy to remove cleanly without solvent

Applications:

- Consumer Products

- Computers, laptops, servers, routers, switches

- LEDs & lighting

- Telecommunications

- Automotive electronics

- Electrical Inversion

- Vibration dampening

- Power PCB’s

| Thin Thermal Gap Pads | Gap Filler Thermal Pads |

| Fiberglass reinforced, cost-competitive and thermally conductive soft gel pads | UV Stability |

| Flame retardant and electrically insulating | UV Resistant Silicone Topping Required |

| Provides shock absorption and easy handling with moderate tackiness | Variable Resistance to Chemicals and Hydrostatic Pressure |

| Applications | Applications |

| fill gaps between low power | low power applications requiring heat transfer across any large air gap |

| heat-generating components and related heat sinks | |

| boards or chassis that require complex, die cut shapes |

Ease of Use

- No equipment, heating, or curing required. Pre-cured stamped parts supplied on a roll with release liner.

Broad Functionality

- Effective as thermal interface/heat-transfer media, dielectric barriers, and stress-relieving shock/vibration absorbers

Flexibility

- High performance and durability over a wide range of temperature and humidity.

- Low durometer gel offers excellent compressibility which allows varying component height with low clamping force.

- Numerous thickness options to fill a large or small gap, while helping to minimize system costs

- Features

-

- Soft/compressible yet resilient and low compression set

- Fully cured for improved thermal cycling without pump-out concerns

- Provides low stress on the component

- Perfect for non-parallel or rough surfaces

- Consistency with manual application and minimal experience

- TIM pads are easy to remove cleanly without solvent

- Applications

-

Applications:

- Consumer Products

- Computers, laptops, servers, routers, switches

- LEDs & lighting

- Telecommunications

- Automotive electronics

- Electrical Inversion

- Vibration dampening

- Power PCB’s

- Thin vs Gap Filler Pads

-

Thin Thermal Gap Pads Gap Filler Thermal Pads Fiberglass reinforced, cost-competitive and thermally conductive soft gel pads UV Stability Flame retardant and electrically insulating UV Resistant Silicone Topping Required Provides shock absorption and easy handling with moderate tackiness Variable Resistance to Chemicals and Hydrostatic Pressure Applications Applications fill gaps between low power low power applications requiring heat transfer across any large air gap heat-generating components and related heat sinks boards or chassis that require complex, die cut shapes - Benefits of Thermal Pads

-

Ease of Use

- No equipment, heating, or curing required. Pre-cured stamped parts supplied on a roll with release liner.

Broad Functionality

- Effective as thermal interface/heat-transfer media, dielectric barriers, and stress-relieving shock/vibration absorbers

Flexibility

- High performance and durability over a wide range of temperature and humidity.

- Low durometer gel offers excellent compressibility which allows varying component height with low clamping force.

- Numerous thickness options to fill a large or small gap, while helping to minimize system costs

Quick Links

[table id=30 /]