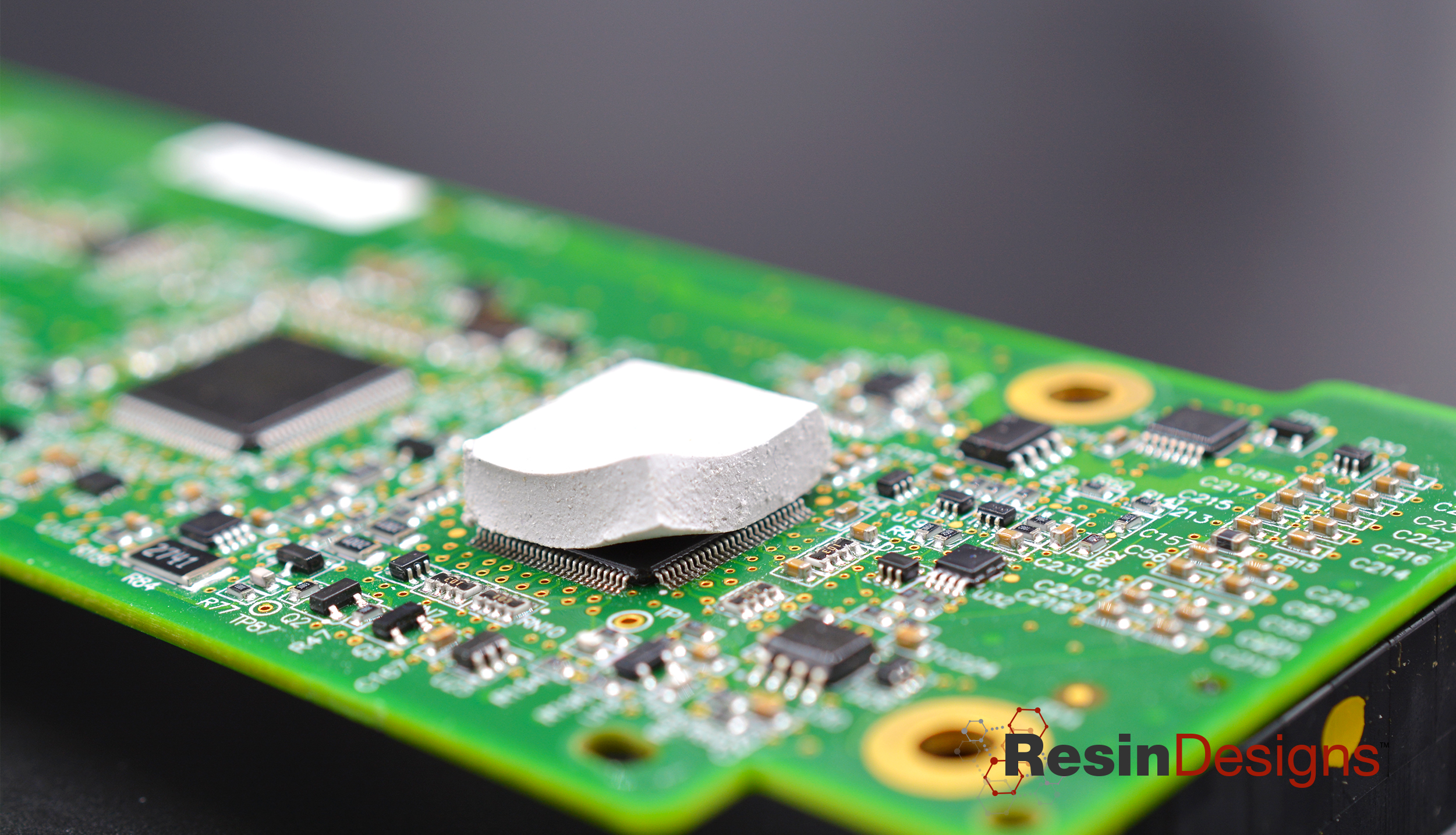

Thermal Management

Control and dissipation of thermal energy is critical to the reliable performance of devices in markets including:

- Aerospace

- Automotive (including EV, batteries, and charging)

- High-Speed Microelectronics and Integrated Circuits

- Power Electronics Including Inverters

Resin Designs development chemists are experts in devising standard and custom solutions to transfer unwanted heat and energy. Products include:

- 2 component thermally conductive liquids

- 1 and 2 component thermally conductive adhesives and encapsulants

- Custom die-cut thermally conductive pads and rolls for cleanliness and ease of application