UV Curable Conformal Coatings(Type AR/UR)

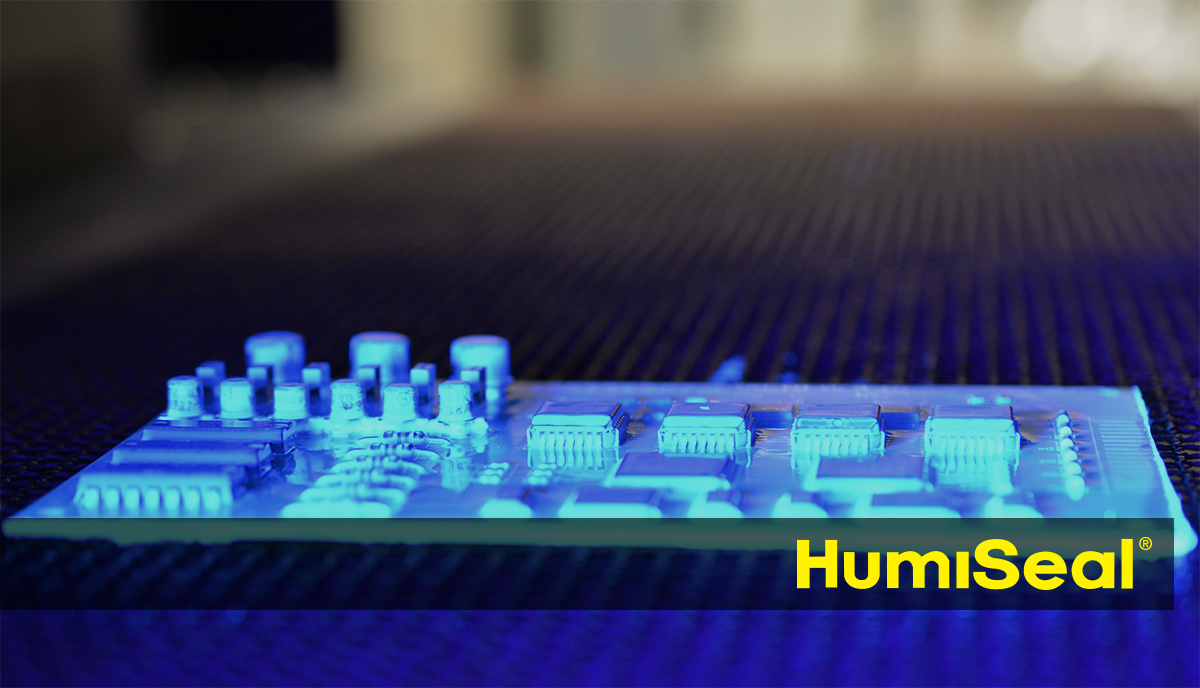

HumiSeal’s UV curable conformal coatings represent an exciting innovation that provides superior performance. When combined with extremely fast curing, allows for short cycle times and maximum production speeds. These products can be sprayed using traditional automated spray equipment with the relatively simple addition of a small-footprint UV light curing unit.

HumiSeal has developed a range of UV curable coatings that are unique within the industry which include:

- 100% solids, with minimal environmental impact

- Superb adhesion to a wide range of commonly used solder resists

- High IR (insulation resistance) and MIR (moisture insulation resistance)

- Resistance to a wide range of solvents

- Great flexibility at a wide range of temperatures

- Secondary moisture cure mechanism for shadowed areas

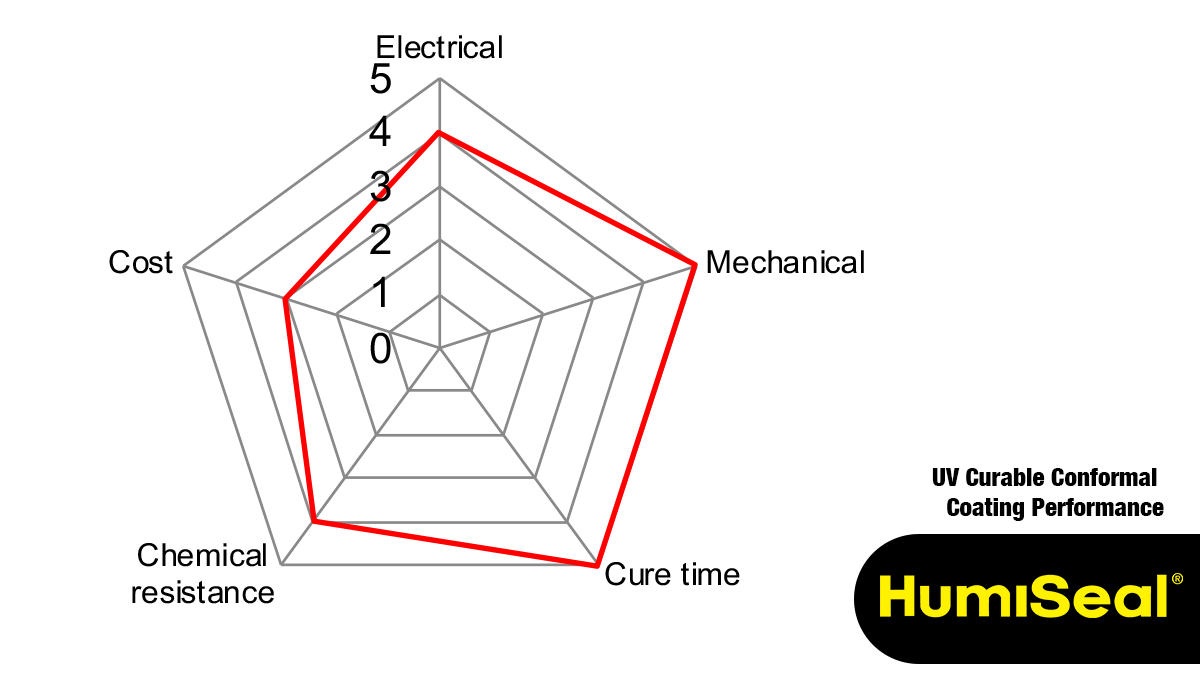

UV Curable Conformal Coating Performance

For the full UV curable (Type AR/UR) product range please click here.

UV Curable Conformal Coating Products

The UV20 family of products are designed to provide protection against vibration and mechanical shocks in electronic devices and PCBs. Dual curing (UV and moisture), single component, high solids coatings and gels. Excellent chemical resistance, flexibility, and moisture resistance. RoHS Directive Compliant.

Unique Features:

- Secondary Cure for Shadow Areas, superior chemical resistance

- Primary Applications: “Staking” of PCB components, vibration and mechanical shock resistance.Learn more

Dual curing (UV and moisture) family of single component, high solids conformal coatings and gels. Excellent chemical resistance, surface hardness, flexibility, and moisture resistance. The UV40 products have been an industry staple for over a decade.

- Unique Features: Secondary Cure for Shadow Areas, superior chemical resistance

- Primary Applications: White Goods, Automotive, Aerospace, Industrial

- Some Products Recognized under UL, MIL-I-46058C, IPC-CC-830. All RoHS Directive 2011/65/EC Compliant,

- Require Full Spectrum (H Style) UV Light for Cure

Higher flexibility, dual curing (UV and moisture) family of single component, high solids conformal coatings. Excellent chemical resistance, surface hardness, flexibility, and moisture resistance. UV 50 products demonstrate improved thermal and mechanical shock performance.

- Unique Features: Secondary Cure for Shadow Areas, superior chemical resistance

- Primary Applications: White Goods, Automotive, Aerospace, Industrial

- Some Products Recognized under UL. All RoHS Directive 2011/65/EC Compliant,

- Require Full Spectrum (H Style) UV Light for Cure

HumiSeal®UVA300 Product Family

LED curable, dual curing (UV and moisture) family of single component, high solids conformal coatings. Excellent chemical resistance, surface hardness, flexibility, and moisture resistance. UVA 300 products use less energy and present fewer hazards compared to traditional materials.

- Unique Features: Single Wavelength (LED) cure, secondary Cure for Shadow Areas

- Primary Applications: White Goods, Automotive, Aerospace, Industrial

- Recognized under IPC-CC-830 and RoHS Directive 2011/65/EC

HumiSeal® UV500 Product Family

Humiseal’s UV500 series conformal coatings represent the third generation of advancement in PCB protection technology. Building on the best qualities of previous product groups including UV40 and UV50, the 500 series advances performance in a number of key properties. UV500 products were designed to be more easily reworked than previously. They also provide the best performance to date in resistance to deformation or cracking under high cycle thermal and mechanical shock tests.

Properties of the UV500 product family include:

- UV curable with secondary moisture cure for shadow areas

- 100% Solids, no solvents, and no thinning required

- Superior resistance to thermal and mechanical shock

- Excellent chemical resistance

- Superior humidity and moisture resistance

- ROHS 2015/863 and China GB 30981-2020 compliant

HumiSeal’s UV80 series conformal coatings are specialty UV-curable coatings designed specifically as low-viscosity alternatives to standard Humiseal UV materials. Similar to other Humiseal UV-curable, UV80 series products cure in seconds of exposure to appropriate wavelength and energy lamps. They are also designed with reliable secondary humidity cure mechanisms for unexposed or shadow areas. The lower viscosity of UV80 series products is especially advantageous to allow flow and leveling when using film and fan coating type selective coating equipment. The UV80 series consists of standard grade which cures with arc or microwave traditional lamps, as well as UV80 LED which cures with single wavelength LED type lighting.

Properties of the UV80 series include:

- Low viscosity suitable for film coater application without the need for pre-heating

- Excellent adhesion

- Excellent moisture resistance

- Fluorescence under UV light to allow coating inspection

- Have a secondary cure mechanism that will fully cure any unexposed areas of the coating within 7 days at ambient conditions to give a transparent solid

- Fungus resistant

UV80 meets the following standards:

- IPC-CC-830 • Compliant with RoHS Directive EU 2015/863

- Compliant with China RoHS 2

- Compliant to China Standard GB30981-202

- Contains no SVHCs to EU REACH 1907 Directive

- UL 94V-0

UV Curable Application Process

Step 1- Select a UV curable conformal coating

Step 2- Pour the coating into the dispenser machine.

Step 3- Application of the UV curable conformal coating automated spraying

Step 4- Pass through the UV cure oven